Call us today!

SILO VENT

Silo Vent

Silo Vent

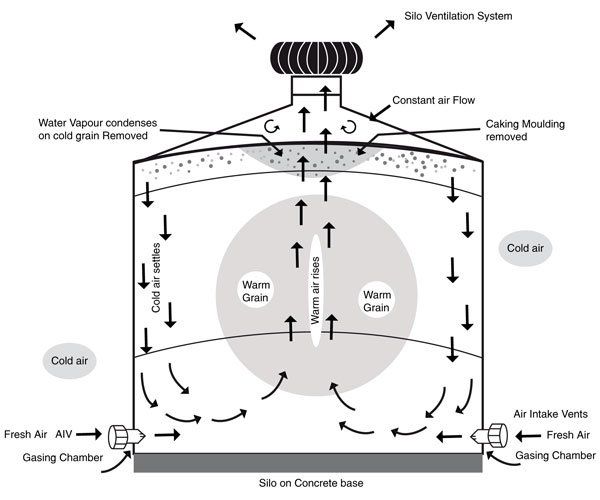

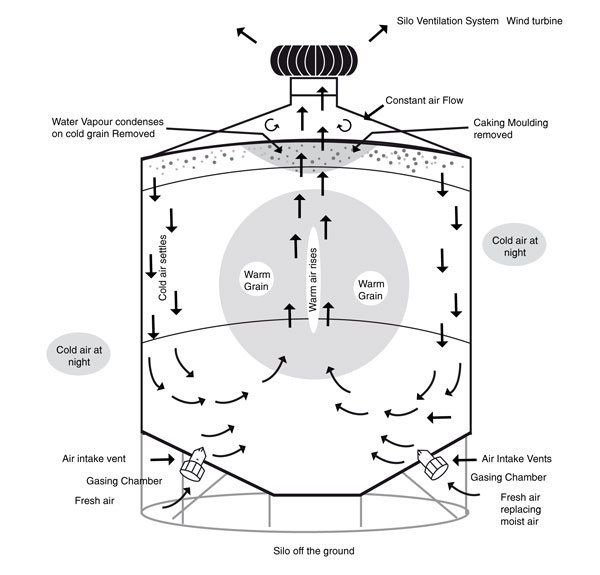

Silo Vent is an energy-efficient unit with a wind-driven ventilator. The heat, humidity and condensation are drawn out through the ventilator, while stabilising the internal temperature of the stored grain. Silo Vent units are environmentally friendly, as they are powered by the wind. There are no running costs with a Silo Vent system: they run for free 24 hours a day, 7 days a week.

Silo Vent has two different units, one for use in all types of non-sealed silos, and the other, the Damper Model, designed for use in sealed silos.

Functions

Silo Vent is a low-cost and maintenance-free way to effectively reduce the inside temperature and humidity of your silos stored with grain or legumes.

The silo ventilator is an energy-efficient system which creates a venturi effect, drawing out the unwanted heat and humidity and allowing fresh air to circulate while stabilising the internal temperature of the stored grain. This can then lead to a reduced optimum breeding environment and temperature for possible insect infestation. Chemicals applied to stored grain could be reduced; however, proper stored grain handling management still needs to be undertaken.

The Silo Vent is best located on the silo cap or lid at the top of the silo. The unit is attached to the lid as a fixture. When filling the silo, tilt or slide the lid to one side as normal, allowing the unit to rest on the silo roof, out of the grain auger’s way.

Benefits

- Reduces inside temperature of a silo.

- Reduces humidity and condensation build-up in silos.

- Exhausts unwanted heat from the top of the silo.

- Replaces and circulates air inside silo.

- The temperature of stored grain or legumes is more stable.

- Reduces mould build up.

- The optimum breeding environment for insects is less favourable.

- The amount of chemicals applied to stored grain can be reduced.

- No electrical powered connection is required.

- Operates 24 hours per day, 7 days a week

- No switches or timers to turn off or on.

- No additional running costs for the unit. It runs for free.

- Easy to install.

- No ongoing maintenance after installation.

- Damper model designed for sealed silos.

Grain Management

The top of any silo is where the heat and condensation are always present and can become an ideal breeding environment for an insect attack.

By reducing the internal temperature and humidity levels at the top of the silo and on the surface of the stored grain, it makes the silo a less attractive option for insects.

Constant air movement reduces the possibility of condensation forming on the walls of the silos and assists with stabilising the temperature of the grain stored.

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Slide Title

Write your caption here

Button

Prices and Ordering Information

Product orders can be made by phoning us

or by using the order form on this page.

Industrial Ventilator Products:

Silo Fumigation Unit Offset (HD 2 SFU)

Price

$350 + GST

Product Code

SFU

300mm Ventilator without Baffle

Price

$300 + GST

Product Code

300V-WOB

Prices do not include freight. Freight is to be organised by the purchaser.

Orders can be picked up from our location.

Distributors

Order Today!

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible

We will get back to you as soon as possible

Oops, there was an error sending your message.

Please try again later.

Please try again later.

Follow Us

Silo Ventilation Systems Pty Ltd

Phone: 0427 346 325 | Website: www.silovent.com

© Copyright 2022 | All Rights Reserved |

Silo Ventilation Systems |

Web Design by

ACM Digital